CASES OF USE

Digitisation of machinery manufacturers

PLC | IoT

SECTOR: Packaging/ Automotive

Results:

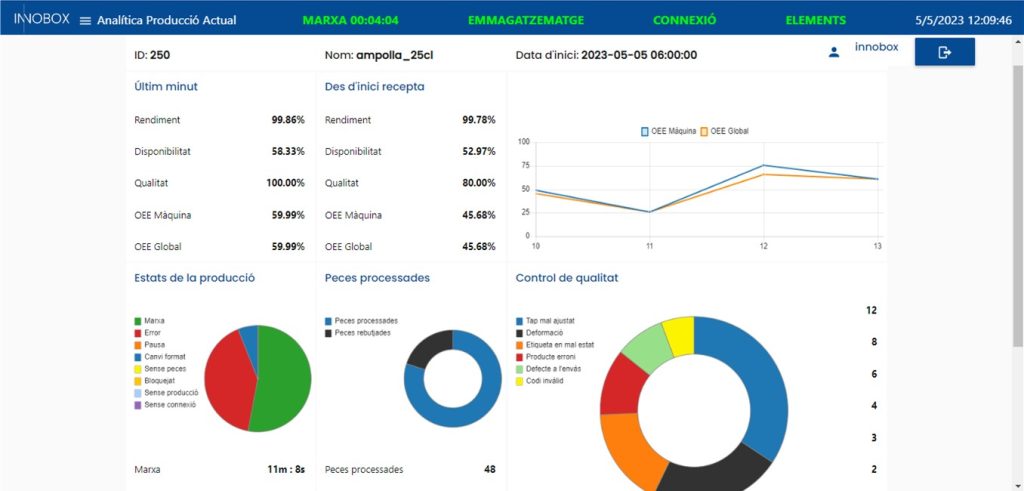

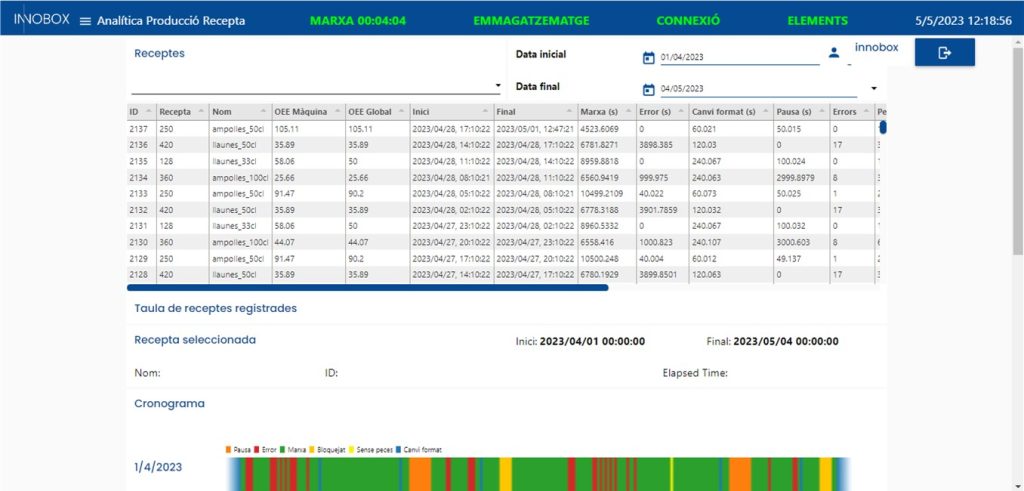

- OEE% production analysis

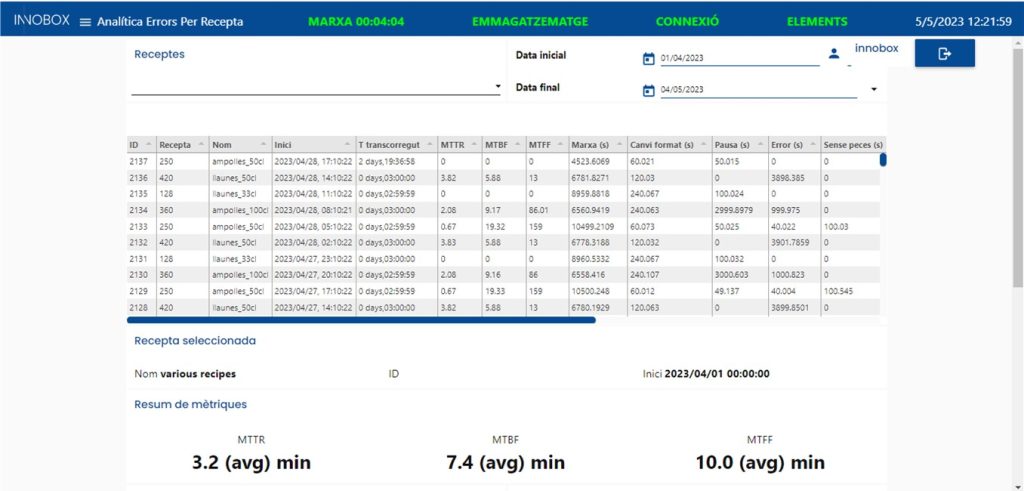

- MTTR,MTBF,MTFF

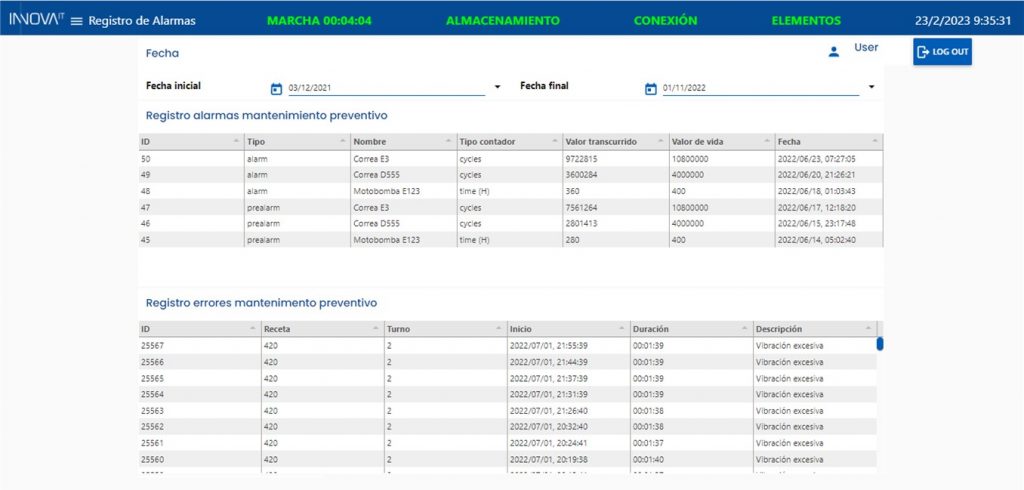

- Alarm analysis

- Failure analysis

- Shift comparison

Digitisation of the press stamping line

PLC | IoT | Machine learning

SECTOR: Packaging/ Automotive

Results:

- Fast and accurate detection of speed dips in production.

- Improved cycle time in automation.

- Reduction of downtime (Mean Down Time).

- Analysis of the main origin of stoppages.

- Analysis of shift production.

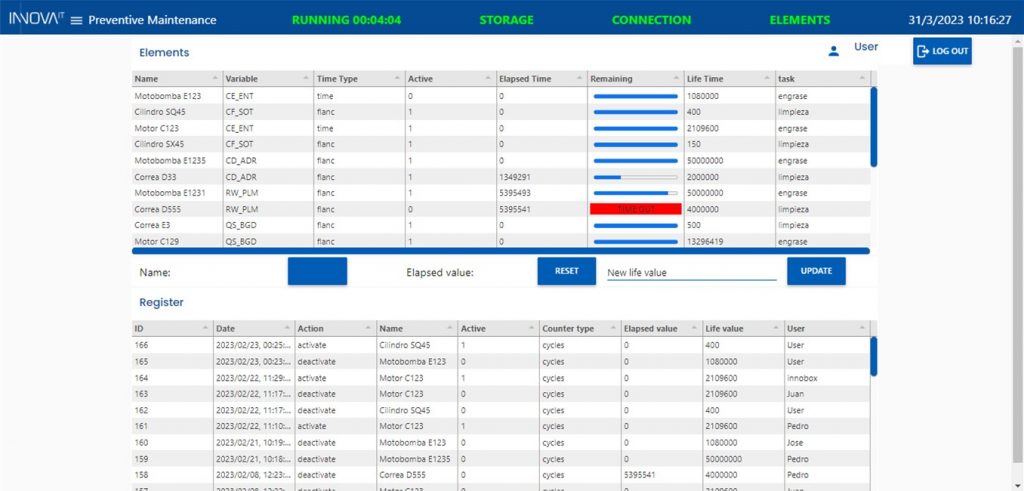

Asset monitoring

IoT | Traceability

SECTOR: Water/ Automotive

- Production batch control

- Advanced quality control

- Specific analysis of the production through the extraction of data during the whole manufacturing process.

Industrial IoT solution to simplify the capture, analysis and exploitation of data from industrial machinery

This solution was applied to a reference company in secondary packaging serving customers in Europe, Latin America, Africa and Asia, operating in sectors such as food, household products, personal care, hygiene, among others. Industrial IoT solution to simplify the capture, analysis and exploitation of data from industrial machinery.

OBJECTIVES

- It allows machinery manufacturers and plant managers to analyse the data and KPI’s of their industrial machines, through a single click, either at the machine without the need for internet or remotely.

- To know the OEE of the installed machines.

- Improve the maintenance service, knowing in real time the alarms and machine failures.

DEVELOPMENT

- Non-intrusive system with PLC control.

- Multi protocol PLC, Ethernet/IP, Allen Bradley, Modbus, OPC UA, etc.

- Can be integrated with customer operating systems ERP, MES, CMMS, SCADA’s, BI.

- Analysis and exploitation of data without the need for internet connection.

- Autonomous monitoring system 24/7, 365 days.

- Reduced downtime and increased productivity.

- Multi-user solution.

RESULTS

- Monitoring of machine performance

- Real-time and historical visualisation of the installed fleet

- Improved transparency and customer satisfaction

- Optimisation and improvement of products and services

- Optimisation of after-sales services