FUNCTIONALITIES

INNOBOX, allows machine manufacturers and plant managers to analyse the data and KPI’S of their industrial machines, through a single click, either on the machine without the need for internet or remotely.

One-click data collection and analysis

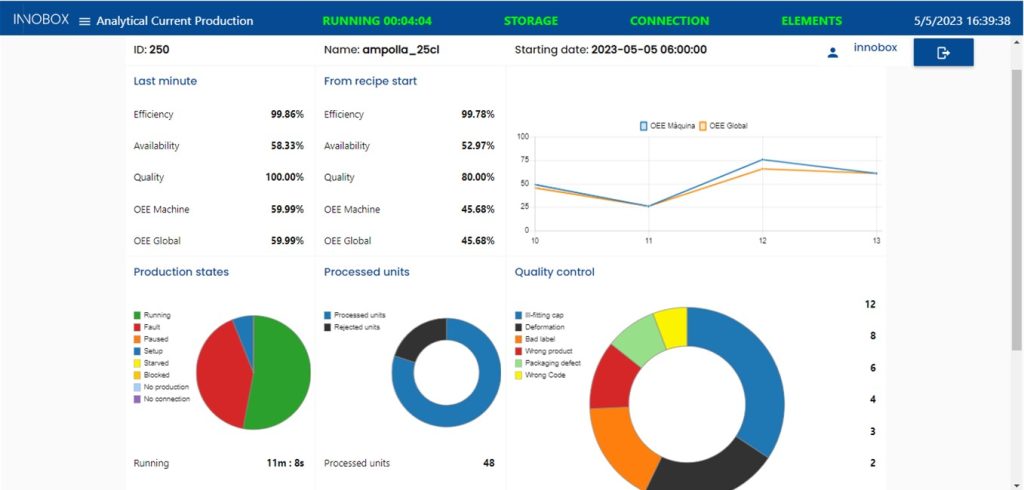

Analytical Current Production

Production data for current production:

- Machine and line OEE

- Efficiency, Availability, Quality

- Type of units produced

- Recipe status (time)

- Machine faults (status time)

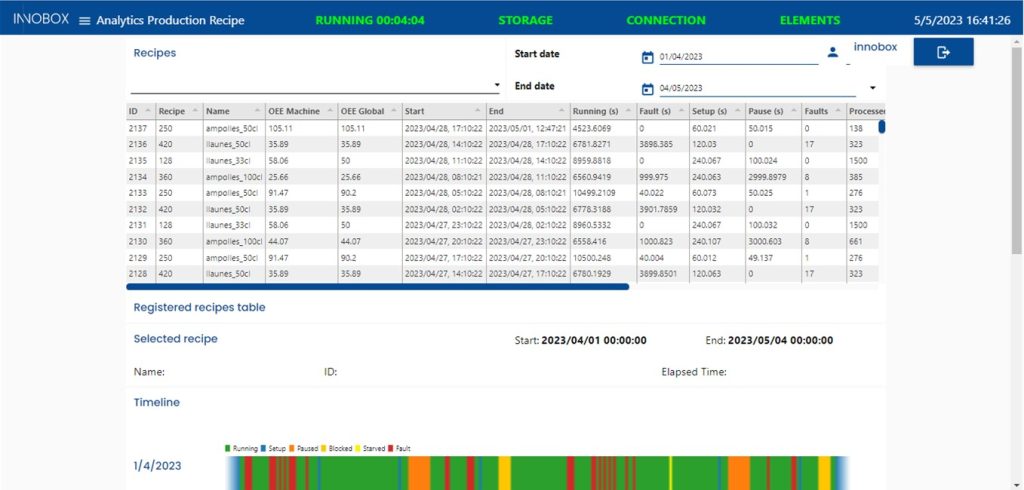

Analytics production recipe

Historical production data by recipe to be filtered by recipe name or date.

- Productivity data

- Details of production statuses

- Efficiency, Availability, Quality

- Counter and typology of units produced

Shift analytics

Data divided according to work shifts (morning, afternoon and evening). It can also be filtered by date to obtain data such as:

- OEE of machine and line.

- MTTR | MTBF

- Counter and type of units produced

- Machine status (time)

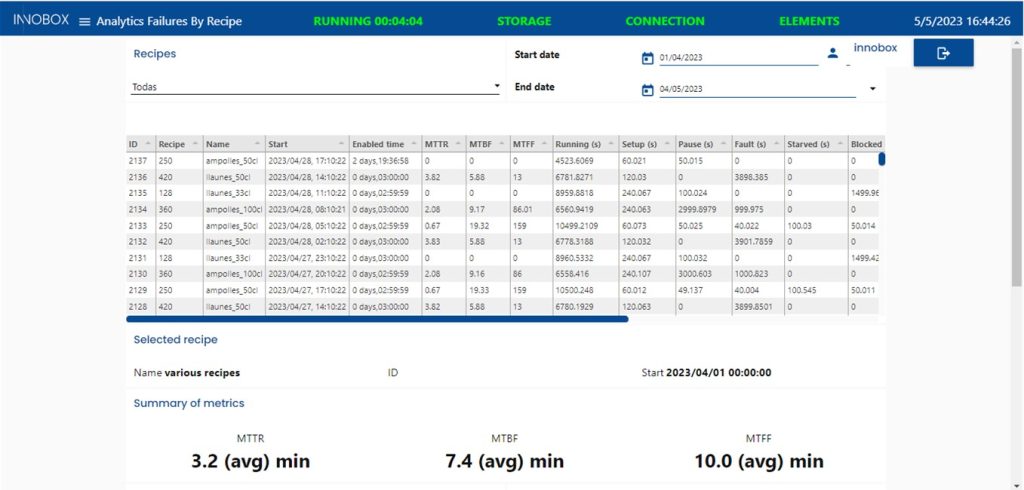

Analysis failure by recipe

Logging of machine faults and corrective times, to be filtered by time interval and recipe:

- MTTR | MTBF | MTFF

- List of machine faults

- Indicator of the type of shutdown: internal/external

- Machine status (time)

- Record of number of faults.

Production Predictive

Production predictive time tool based on analysis of historical record distribution and quality, for current or selected recipe.

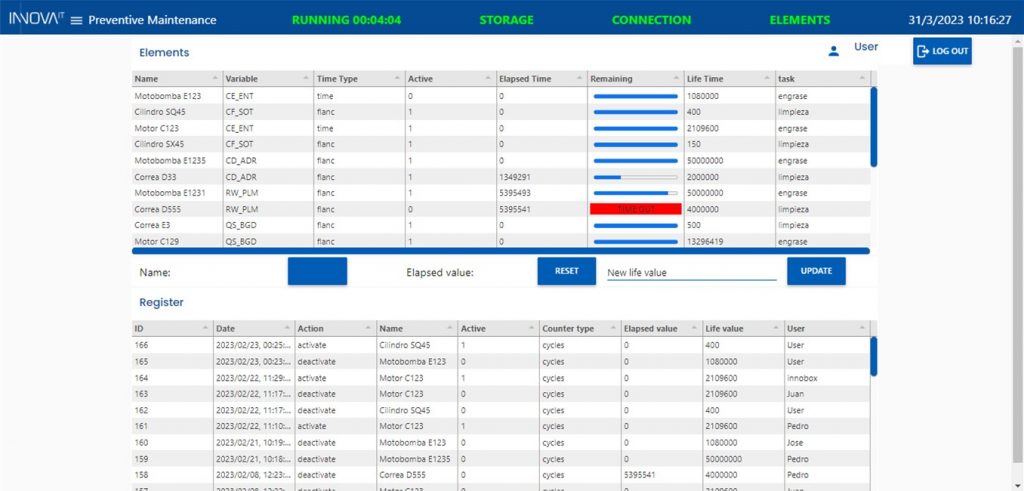

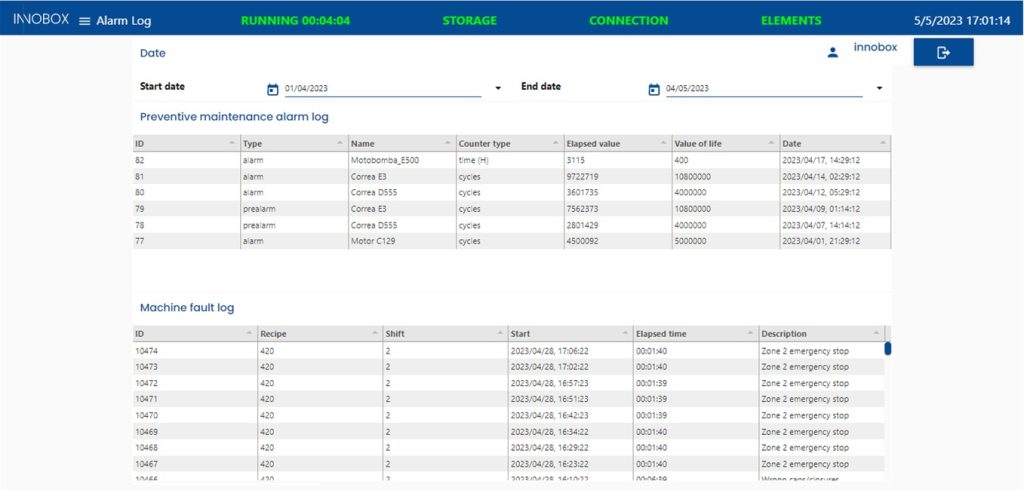

Preventive maintenance

List of machine elements with elapsed value and lifetime value of this element, as well as the maintenance task to be performed and control of these values.

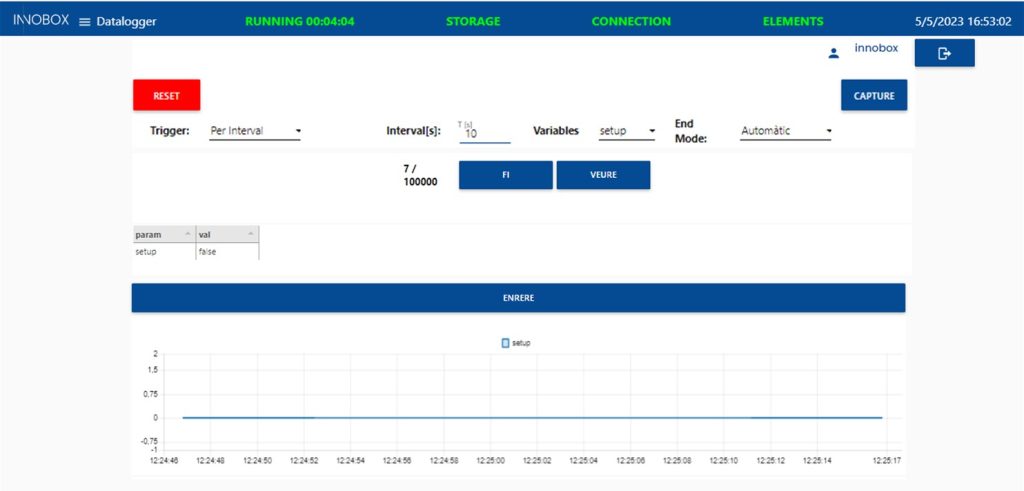

Datalogger

Real-time data logging for monitoring and correlating process variables. Allows indepth analysis of a process, based on event-driven monitoring of signals and timers.

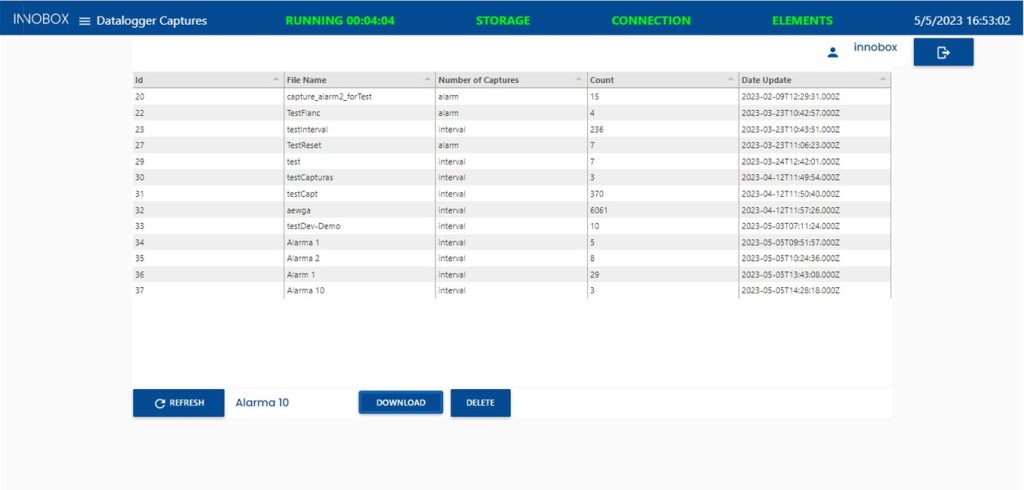

Datalogger captures

Historical record of datalogger captures. Allows download as csv or delete.

Alarm log

Logging of alarms and errors for preventive maintenance that can be filtered by date.

Cloud platform service, where you can have control of all your machines and access your data from any device through a web browser.

In addition, INNOBOX CLOUD allows you to analyse the data from all your machines together, making it possible to compare them and exploit the information on an individual basis.

- Remote operation of machine data

- Statistical analysis between machines

- API, to share information with other data exploitation systems, MES, BI, CMMS, SCADA, etc.

- Secure connection via VPN and SSL data encryption.

Connection with other systems

Efficiency optimiser

- Transfer of know-how from manufacturer to customer.

- Optimisation of machine set-up.

- Optimisation of production speed.

Predictive maintenance

- Reduction of failures, breakdowns and interventions.

- Prolongation of the useful life of the equipment.

- Increased availability of equipment.

- Reduction of downtime for repairs.

Predictive quality control

- Reduction of quality errors.

- Detection of patterns in the manufacturing process.

Local

Remote maintenance

- 24/7 maintenance service.

- Proactive maintenance.

- Time and cost reduction.

- Non-invasive support.